Design and building subsea ballvalve

Subsea ballvalve – design, building, testing and documentation

Customer stories – Reference sheet

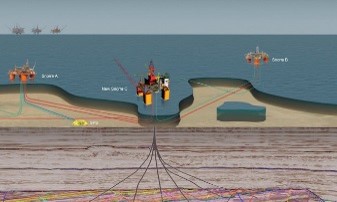

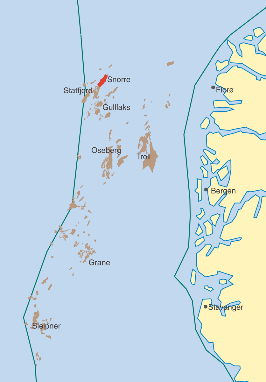

Equinor Snorre 2040

Location: North Sea

Period: 2018 – 2019

Client: TechnipFMC, Kongsberg

Field of application : Sub sea trunnion mounted ball valve

As oil and gas becomes more difficult to extract from high pressure ultra deep oceans and high temperature wells, we appreciate that the continuous reliability of our product is of the outmost importance.

We have Research and Development facilities in-house and our valves are subject to full PR2 temperature and hyperbaric testing to the valve life cycle performance at an equivalent of up to 10 000 feet.

Valve components are subjected to full hardness testing to ASTM E10 and E18, and all valves are subjected to full factory acceptance testing (hydrostatic and pneumatic) and flushed to SAE AS4059 Class 6-BF (ISO 4406) as a minimum prior to despatch API6A-PSL 3G/NACE MR01-75/ASME VIII DIV2.

– Lifetime extension to 2040

Haland Instrumentering AS responsibilities and deliveries:

- Design owner

- Production drawing

- Metal to metal seal design

- Sufficient testing regime

- Helium test

- Testing routines

Related lifetime extension services from Haland Instrumentering AS:

– Fire & Gas Field Equipment

– Level & Flow upgrade